|

| December 04, 2018 | Volume 14 Issue 45 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Hardware and software tools overview for lab-based shock and vibration simulation and testing

By Steve Hanly, Vice President of Sales and Marketing, Midé Technology Corporation

Shock and vibration testing in the field is a great way to get operational data on a system's response to its environment and/or to quantify the environment in which it will operate. But as the design process advances and prototypes are constructed, performing some controlled shock and vibration testing in the laboratory can be advantageous. The purposes of laboratory testing include qualification testing during the design process or to meet test or regulatory standards, fatigue testing, modal analysis, and evaluating performance characteristics.

General Shock and Vibration Test Hardware

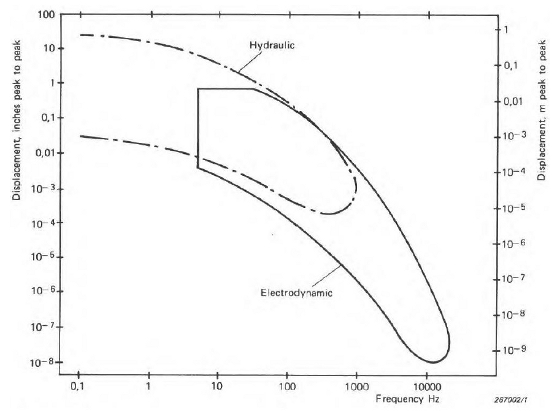

Electrodynamic (ED) and hydraulic are the two main types of vibration shakers/exciters used in general shock and vibration testing. Figure 1 compares the operating ranges of these two types of exciters. Electrodynamic shakers are much more common because of their wider frequency range, linear behavior, and wide range of operating conditions (shock and SRS pulses in addition to vibration). However, for maximum displacement and lower frequency ranges, a hydraulic shaker (Figure 2) is preferable.

Figure 1: The useful operating regions of hydraulic and electrodynamic vibration shakers.

Midé uses an electrodynamic shaker for shock and vibration testing, including calibration of our Slam Stick data loggers. Electrodynamic shaker manufacturers include Brüel and Kjaer, Data Physics, and Unholtz-Dickie. The downside of buying these larger general-purpose shakers for a company's lab is their high cost, which is typically in the tens of thousands of dollars and doesn't even include the cost of the amplifier and software to run the shaker (which add tens of thousands more to the budget).

Figure 2: A large general-purpose shock and vibration shaker.

Modal Testing

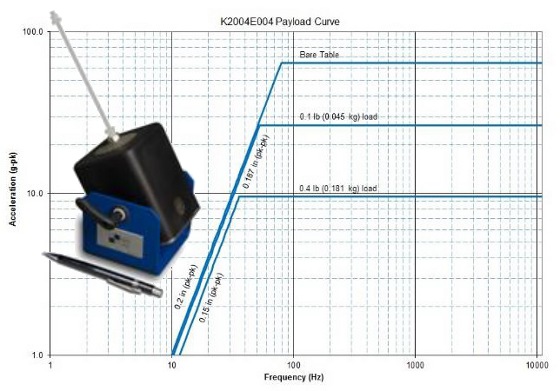

Shakers are also used extensively in modal testing, i. e., the form of vibration testing in which the natural (modal) frequencies, modal masses, modal damping ratios, and mode shapes of an object under test are determined. For this type of test, a much smaller shaker is typically needed to excite the range of modal frequencies of interest. Figure 3 shows an image and performance plot of a mini-shaker that's ideal for general-purpose testing on small components and as an excitation source for modal testing.

Figure 3: A mini-shaker and its payload curve.

An impact hammer offers another approach to exciting a structure for modal testing. Impact hammers are not only more cost effective than shakers (typically less than $1,000), but many experts prefer them for these applications. An impact hammer will provide a nearly constant force over a broad range of frequencies (specified by the type of tip used), so they can excite a broad range of resonances and modal shapes. These hammers will come force-instrumented so that the frequency response function can be calculated using the output of modal accelerometers located throughout a structure.

Testing Labs

Performing shock and vibration testing in a simulated environment can be very expensive because it requires complex equipment and setups. However, there are test laboratories that specialize in shock and vibration testing, although their services can be costly as well. Some can even handle MIL-S-901D shock testing, which involves exploding a charge underwater to subject a test setup to a large displacement shock event.

Vibration Analysis Software

Setting up test hardware and knowing what/how to analyze the vibration data is meaningless without the means to perform that analysis. Software is also typically needed to acquire the vibration data in the first place. But before the test engineer can decide on a specific software option or combination of options from the wide variety of software packages available, it's important to answer two questions:

- Does the application require analyzing shock/vibration data in real time, or can it be post-processed?

- Does the test engineering team have the resources to develop analysis and simulation programs in-house, or would it make more sense to use a standalone graphical user interface (GUI)?

If the hardware chosen to acquire the data can also export it (such as a datalogger), then the software need only handle the post-processing. However, applications that require real-time (or near real-time with a buffer) data streaming and analysis (such as in typical modal analysis and controls applications in which an action is taken based upon recorded data) will limit the options available.

Although writing custom analysis and simulation programs will require some advanced knowledge of the computing language and analysis fundamentals, that's the preferred approach for most post-processing analysis applications. Standalone GUIs are nice for providing that initial overview of the data and performing some analysis. Many applications, however, require doing analysis based upon certain conditions specific to the test. For example, for a two-hour-long test performed on an aircraft component, it might be necessary to develop a script that scans the data and runs FFTs if/when certain conditions are met. Performing this fairly simple analysis that includes a number of if-statements might be more difficult when using a standalone GUI. A combination of standalone GUIs and custom analysis scripts will typically offer the best of both worlds to complete the analysis.

Many software options are available for use in vibration/shock analysis; here are some of the best-known ones.

MATLAB®

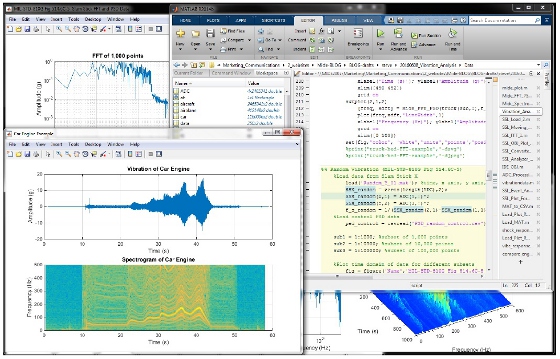

MATLAB is a desktop environment/programming language specifically developed for linear algebraic operations and a hugely popular tool for data analysis. Many engineers begin using it in college; commercial licenses for this software cost more than $2,000, and each additional toolbox adds to the total. I recommend the signal-processing toolbox for vibration analysis.

Figure 4: MATLAB is the most commonly used programming tool for vibration analysis.

If code base programming seems too daunting, MathWorks also offers the Simulink® block diagram environment, which is often used in conjunction with MATLAB. This compelling product can help reduce human programming induced errors and allow teams of analysts to integrate their algorithms a little easier. Simulink also lets engineers interface with hardware produced by National Instruments, Raspberry Pi, and Arduino, but these hardware supports can be costly. Simulink is great for analyzing data in real time and offers incredible customization in addition to built-in analysis capabilities.

Python®

Python is a free, open-source, and highly versatile object-oriented programming language. Its NumPy and SciPy libraries have functions similar to MATLAB. When compared with MATLAB, Python is an elegant and intuitive programming language. It was created to be a generic language that is easy to read. Python is widely accepted as a better alternative to MATLAB for programming needs other than data analysis.

However, MATLAB and Python have advantages and disadvantages for vibration analysis. We recently did some testing to compare MATLAB and Python for vibration analysis and came to the conclusion that, for basic analysis (including FFTs), Python can match and even beat MATLAB computation times, but the programmer may need to do a bit of digging to find and download all the necessary free libraries.

As a MATLAB user, I've found the Anaconda distribution of Python and its most popular libraries very helpful. The Spyder development environment (Figure 5) has a look and feel similar to MATLAB for those with MATLAB experience.

Figure 5: The Spyder Python development environment has an interface similar to MATLAB.

Python is gaining popularity because it's free, and the Python community is generating a wide variety of versatile libraries that are publicly available through GitHub, including the PyDAQmx library that interfaces with National Instruments' drivers.

LabVIEW®

Most engineering companies probably already have a couple of LabVIEW licenses for interfacing with their National Instruments' data acquisition hardware and analyzing data in real time. LabVIEW is a development environment specifically designed for engineers and scientists analyzing data, so it's a popular tool for vibration testing. Designing analysis programs with LabVIEW can be easier for those with less programming knowledge because of the graphical programming language it uses.

Vibration analysts might find LabVIEW's Sound and Vibration Toolkit useful.

Standalone Vibration Analysis Software

There are many standalone software packages available for free or for purchase; here are a couple of the free ones:

- Vibrationdata: Tom Irvine offers both MATLAB and Python versions of this signal analysis and structural dynamics software GUI. The GUI is easy to work with, but all the source code is available if needed to perform custom analysis.

- Slam Stick Lab: Midé's Slam Stick Lab is available for free, along with some example recording files. This software currently only works with Slam Stick recording files and only has basic analysis capabilities, but it includes the major ones typically needed: FFT, PSD, spectrogram, unit conversion, and general plotting. Data can be exported to MATLAB or CSV (readable by Excel, Python, and other software) for follow-on analysis.

Many different commercial standalone GUIs are available for vibration analysis. Although far from free, they offer a big time-savings advantage over writing code in-house.

- m+p International: This company, part of TME Systems, specializes in vibration testing, specifically modal. In addition to a variety of hardware products for data acquisition, they offer some software packages for post-processing and analyzing data in real time. Their SO Analyzer can interface with their hardware for real-time analysis, but it is also useful for handling large datasets and post-processing vibration data.

- VibrationVIEW: VibrationVIEW software from Vibration Research is another alternative for post-processing and analyzing vibration data in real time.

- Brüel and Kjaer: A number of their software packages are very impressive for both post-processing and analyzing vibration in real time.

- ProAnalyst: This software from Xcitex is unique in that it uses video for determining vibration levels and analyzing them.

- FEMtools: This is a very powerful tool for modal analysis and validating CAD models with experimental data; it can also be used for general post-processing of time history vibration data.

About the author

About the author

Steve Hanly is Vice President of Sales and Marketing for Midé Technology Corporation. He joined the company as an engineer in 2010 and has since held a number of engineering, product management, and marketing positions with the company. Hanly holds an undergraduate and master's degree in mechanical engineering and aerospace engineering, both from Worcester Polytechnic Institute, and is currently in an MBA program from University of Massachusetts, Amherst.

Published December 2018

Rate this article

View our terms of use and privacy policy